OUR SERVICES

In GLOTRAINCERT LTD, we offer high impact technical services and training programs to Oil and Gas, Power Generation, Airlines, Construction Industries among others. Our technical training and service are inline with international code and standard.

ASNT NDT TECHNICAL TRAINING SERVICES

We offer the following ASNT NDT Certification Training

- Magnetic Particle Testing (MT)

- Liquid Penetrant Testing (PT)

- Radiographic Testing (RT)

- Ultrasonic Testing (UT)

- Visual Testing (VT)

- ADVANCED NDT

- Electromagnetic Testing (ET)

- Acoustic Emission Testing (AE)

- Leak Testing (LT)

- Thermal/Infrared Testing (IR)

- Vibration Analysis (VA)

- Neutron Radiographic Testing

MAGNETIC PARTICLE TESTING (MT)

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface

discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys.

The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. The presence of a surface or subsurface discontinuity in the material allows the magnetic flux to leak, since air cannot support as much magnetic field per unit volume as metals.

To identify a leak, ferrous particles, either dry or in a wet suspension, are applied to a part. These are attracted to an area of flux leakage and form what is known as an indication, which is evaluated to determine its nature, cause, and course of action, if any

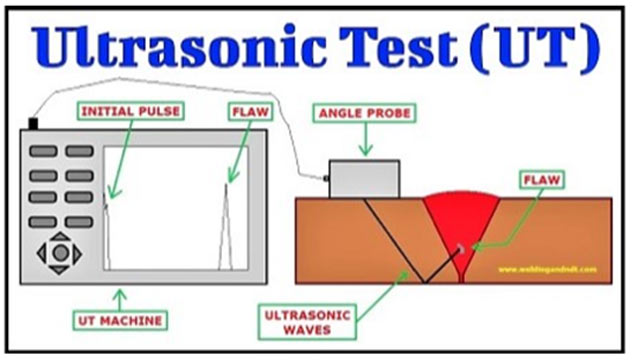

ULTRASONIC TESTING (UT)

Ultrasonic testing uses special equipment to send high frequency sound waves to penetrate a material's to determinations material thickness, soundness, and discontinuities or defects.

What UT Can Be Used For:

- Flaw detection/evaluation

- Thickness measurement of materials

- Dimensional measurements,

- Material characterization

- Determinations material condition and discontinuities etc

ULTRASONIC TESTING (UT)

RADIOGRAPHY TESTING / RADIOGRAPHIC FILM INTERPRETATION

Radiography Testing is a test conducted on a welded or casting component by way of inducing radiation into the component and using a film which shows the internal image condition of the component; the image on the film will be seen and examined using a radiographic viewer.

RT is a way of passing penetrating radiation through an object, and recording the emerging radiation on a film RT involves using penetrating gamma- or X-radiation on materials and products.

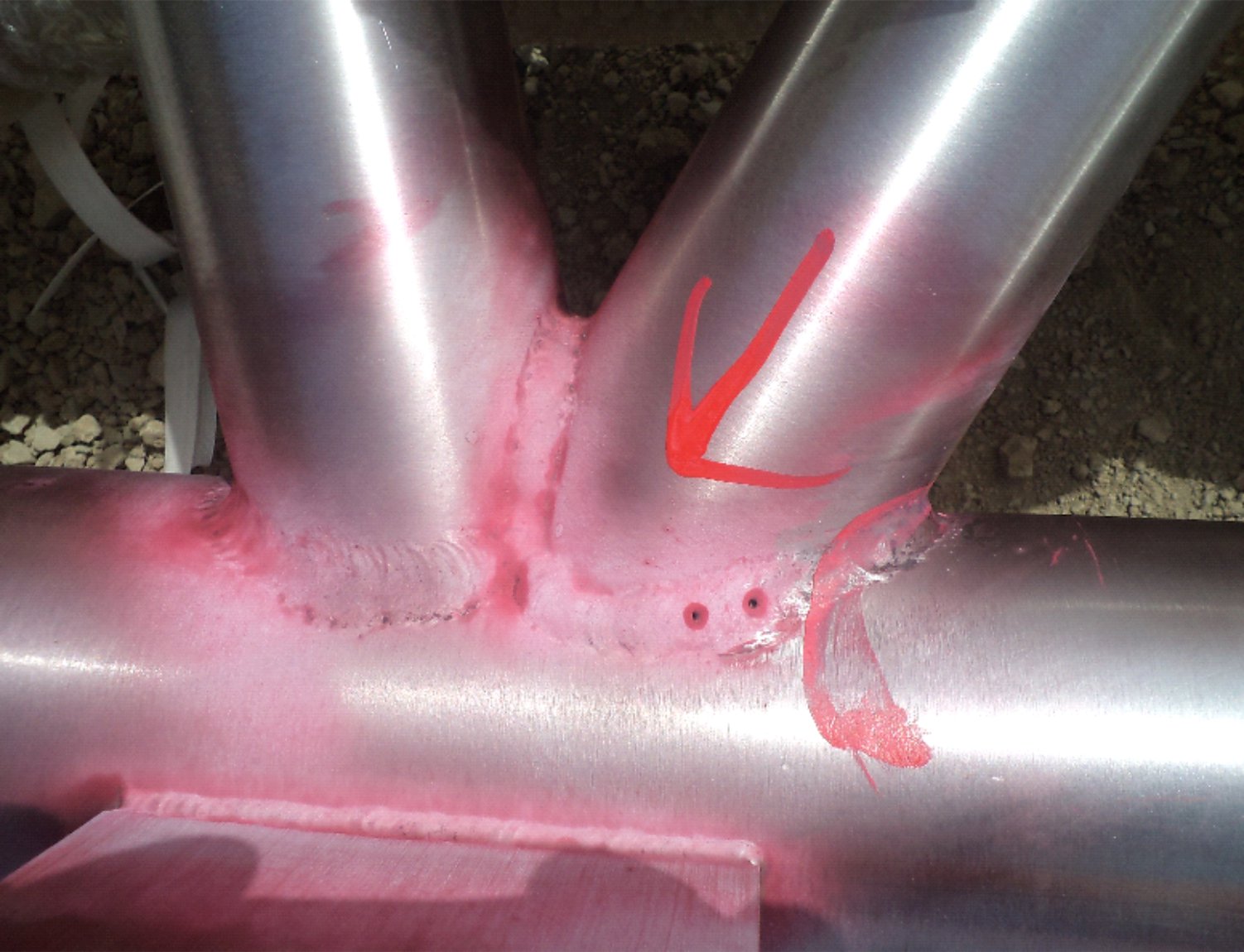

PENETRANT TESTING

The principle of liquid penetrant testing is that the liquid penetrant is applied on the material surface and after a dwell time , it is drawn into the surface-breaking crack by capillary action and excess surface penetrant is then removed; a developer (typically a dry powder) is then applied to the surface, to draw out the penetrant in the crack and produce a surface indication of the crack or defects.

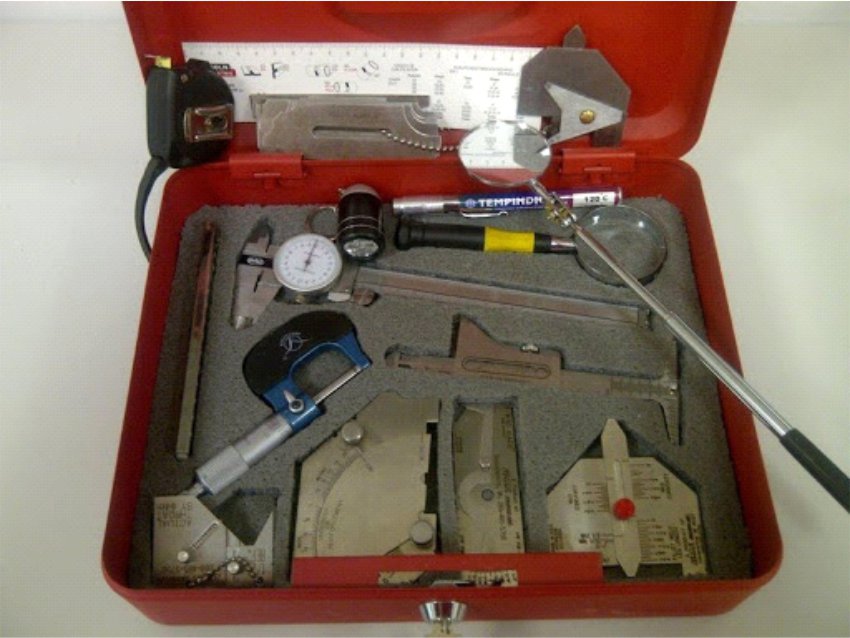

Visual Testing

It is the process of looking over a piece of equipment using the naked eye to look for flaws. It requires no equipment except the naked eye of a trained inspector.

Visual inspection can be used for internal and external surface inspection of a variety of equipment types, including storage tanks, pressure vessels, piping, and other equipment.

Visual inspection is simple and less technologically advanced compared to other methods.

LIFTING CERTIFICATION TECHINICAL TRAINING SERVICES

GLOTRAIN CERT LTD Coating Inspection Services Offer the following:

- Rigger Course

- Banksman & Slinger Course

- Lifting Gear & Equipment Course

- Lifting & Slinging Course

- Forklift Operation & Inspection Course

- Crane Operation & Inspection Course

HEALTH & SAFETY

TECHINICAL TRAINING SERVICES

We Offer Health & Safety Technical Training Services:

- NEBOSH

- IOSH

- General Health and Safety Course

- Risk Management Course

- Confined Space Entry & Rescue

- Health and Safety Mgt System

- Working At Height Safety Course

- Permit To Work Safety Course

- Lifting Equipment Safety Course

- Radiation Protection Safety Course

- Forklift Safety Course

- Crane Safety Course

America Petroleum Institute

Individual Certification Programs (ICP)

Technical Training Course

API Individual Certification Programs (ICP)

API Individual Certification Programmes are designed to promote self-regulation, health and safety, improved inspection capabilities, and improved management control and environmental performance.

Certified inspectors are recognised as working professionals who are fully knowledgeable of industry inspection codes, and who are performing their jobs in accordance with those requirements. API’s Individual Certification Programmes (ICP) are based on industry developed standards that are recognised and used with confidence worldwide.

API ICP CERTIFICATION TRAINING COURSE

API 510 – Pressure Vessel Inspection

API 570 – Piping Inspection

API 653 – Tank Inspection

API 571 – Material & Corrosion Inspection

API 580 – Risk Based Inspection

WELDING & WELDING INSPECTION CERTIFICATION

TECHINICAL TRAINING COURSES

AWS/CWI Certified Welding Inspector Preparation Course:

• TWI/CSWIP 3.1 welding Inspector Preparation Course

• TWI/CSWIP 3.2.2 Senior Welding Inspector Preparation Course

• Welding Technology & Processes

• Welding Inspection & Measurements

• Welding Metallurgy & Heat Treatment

• WPS, PQR, WPQ Overview & preparation and Electrode Selection

• Material Selection, Receiving and review of Mill Test Certificates

CODES AND STANDARDS TECHINICAL

TRAINING COURSES:

• Codes, Standards & Specifications

• ASME B31.1 Power piping Design, Fabrication & Inspection

• ASME B31.3 Process Piping Design, Fabrication & Inspection

• ASME VIII Div.1 Pressure Vessel design, Fabrication & Inspection

• AWS D1.1 Structural Steel Welding Code

• API 1104 Pipeline Construction

• ASME IX welding Procedure & Welder Qualification Code

• ASME V Non-Destructive Examinations Code